Presse idrauliche doppia/quadrupla colonna usato in vendita (322)

Ordina i risultati

- Prezzo più basso Prezzo più alto

- Annunci più recenti Annunci più vecchi

- Distanza più breve Distanza più lunga

- Anno di costruzione più recente Anno di costruzione più vecchio

- Aggiornamento più recente Aggiornamento più vecchio

- Fabbricante da A a Z Fabbricante da Z ad A

- Rilevanza

- Prezzo più basso

- Prezzo

- Prezzo più alto

- Prezzo

- Annunci più recenti

- Data pubblicazione

- Annunci più vecchi

- Data pubblicazione

- Distanza più breve

- Distanza

- Distanza più lunga

- Distanza

- Anno di costruzione più recente

- Anno di produzione

- Anno di costruzione più vecchio

- Anno di produzione

- Aggiornamento più recente

- Ultimo aggiornamento

- Aggiornamento più vecchio

- Ultimo aggiornamento

- Fabbricante da A a Z

- Produttore

- Fabbricante da Z ad A

- Produttore

- Denominazione dalla A alla Z

- Denominazione

- Da Z a A

- Denominazione

- Modello da A a Z

- Modello

- Modello dalla Z alla A

- Modello

- Riferimento più basso

- Riferimento

- Riferimento di massimo livello

- Riferimento

- Tempo di esercizio più breve

- Periodo di pubblicazione

- Durata di funzionamento più lunga

- Periodo di pubblicazione

- Rilevanza

- Rilevanza

Macchine per la lavorazione del metallo, macchine utensili Presse Presse idrauliche doppia/quadrupla colonna

Annuncio economico

Turchia

Turchia

1.354 km

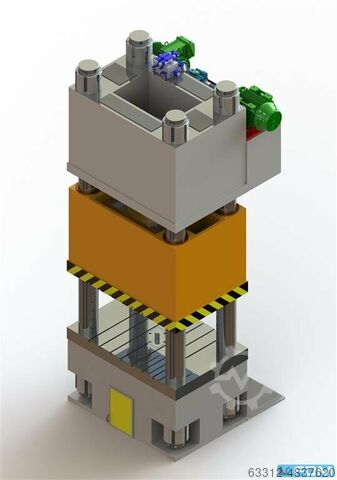

PRESSA IDRAULICA PER IMBUTITURA PROFONDA TIPO H 200/70 TON

CRONOSSTECHCHSP 200/70

Chiama

Condizione: nuovo, Anno di produzione: 2025, forza di pressatura: 200 t, larghezza tavola: 1.000 mm, lunghezza del tavolo: 1.200 mm, forza di retrazione: 70 t, corsa: 800 mm, pressione di esercizio: 250 barra, Equipaggiamento: barriera di sicurezza a luce, documentazione / manuale, CRONOSSTECH CHSP 200/70

H-Type Hydraulic Deep Drawing (Spinning) Press – 8-Guided Sliders

General Description

The CRONOSSTECH CHSP series H-type hydraulic deep drawing presses are developed with a double-acting working principle, ensuring controlled material flow for sheet metal forming, deep drawing, and spinning applications. The 8-guided H-frame structure provides maximum rigidity during pressing, maintaining stable parallelism and perpendicularity tolerances throughout the stroke.

The CHSP 200/70 model, with a 200-ton main ram and a 70-ton cushion (blankholder) capacity, is designed for medium to high tonnage deep drawing and spinning operations. The frame construction is stress-relieved by vibration method to ensure long life and reliable operation.

⚙️ Standard Equipment

- Steel construction, 8-guided H-frame press body

- Vibration stress relieved frame structure

- Bronze Zr14 slide bearings

- WPQR and WPS welding applications approved by TÜRK-AK accreditation (EN ISO 15614-1:2017 / EN ISO 14731)

- Design and manufacturing in accordance with CE standards

- PLC-controlled hydraulic system

- 7” DELTA touch screen panel

- Adjustable ram and cushion stroke control

- Adjustable ram and cushion tonnage (pressure) control

- Automatic lubrication system

- Electronic filter contamination warning system

- Monitoring of hydraulic unit oil temperature and system status on screen

- Cooling system

- Off-line filtration

- Safety systems for operator protection

- SIEMENS – SCHNEIDER switchgears

📐 Technical Specifications – CHSP 200/70

Type: Steel construction, 8-guided H-frame press body

Frame Material: St52 – ERDEMİR

Slide Bearings: Bronze Zr14

Capacity (Ram): 200 Ton

Capacity (Cushion): 70 Ton

Moving Table Dimensions: 1000 × 1200 mm

Fixed Table Dimensions: 1000 × 1200 mm

Parallelism Tolerance: 120 micron/meter

Perpendicularity Tolerance: 60 micron/meter

Stroke (Ram): 800 mm

Stroke (Cushion): 300 mm

Min. Open Height: 100 mm

Max. Open Height: 900 mm

Stress-Relieving: Vibration method

Welding Application: Certified by TÜRK-AK-accredited WPQR and WPS (EN ISO 15614-1/2017, audits by welding coordination engineers certified to EN ISO 14731)

Max. Working Pressure: 250 Bar

Total Motor Power: 22 kW – IE3

Main Pump: 32 cm³ – REXROTH or PARKER

Moving Table Fast Down Speed: 150 mm/sec

Moving Table Drawing Speed: 12 mm/sec

Moving Table Return Speed: 170 mm/sec

Cushion Forward Speed: 30 mm/sec

Main Cylinder Bore: Ø320 mm – Ck45

Cushion Cylinder Bore: Ø190 mm – Ck45

Auxiliary Acceleration Cylinders: 2 units

Approx. Press Height: 3800 mm

Approx. Press Width: 2950 mm

Approx. Press Depth: 2200 mm

Bottom Table Height from Floor: 1350 mm

Pre-Fill Valve: NG 125

Ppodpfxex N T U Ts Aaqsl

Hydraulic Unit: REXROTH or PARKER

Cooling System: EMMEGI – CIESSE – PARKER

Off-line Filtration: REXROTH or PARKER

Linear Distance Ruler: NOVATECHNIK or TURCK

PLC Application: DELTA

Touch Screen Panel: DELTA 7”

Switchgears: SIEMENS – SCHNEIDER

Approximate Weight: 13.5 Ton

Production Note

This machine is manufactured in Türkiye by CRONOSSTECH.

Annuncio economico

Turchia

Turchia

1.354 km

Pressa idraulica per stampaggio profondo tipo H 150/50 tonnellate

CRONOSSTECHCHSP 150/50

Chiama

Condizione: nuovo, Anno di produzione: 2025, forza di pressatura: 150 t, larghezza tavola: 1.000 mm, lunghezza del tavolo: 1.200 mm, forza di retrazione: 50 t, corsa: 600 mm, pressione di esercizio: 250 barra, Equipaggiamento: barriera di sicurezza a luce, documentazione / manuale, CRONOSSTECH CHSP 150/50

H-Type Hydraulic Deep Drawing (Flanging) Press – 8-Guided

General Description

The CRONOSSTECH CHSP series H-type hydraulic deep drawing presses are designed with a double-acting working principle to ensure controlled material flow for sheet metal forming, deep drawing, and flanging applications. The 8-guided H-frame structure provides maximum rigidity during the pressing cycle; parallelism and perpendicularity tolerances are consistently maintained throughout the stroke.

The CHSP 150/50 model is engineered for precise and repeatable deep drawing applications, featuring a main ram capacity of 150 tons and a blank holder (pot) capacity of 50 tons. The frame construction is stress-relieved by vibration to ensure long-lasting and reliable operation.

⚙️ Standard Equipment

- Steel construction, 8-guide H-frame press body

- Vibration stress-relieved frame structure

- Bronze Zr14 slide bearings

- WPQR and WPS welding procedures accredited by TÜRK-AK (EN ISO 15614-1:2017 / EN ISO 14731)

- Design and manufacturing in accordance with CE standards

- PLC-controlled hydraulic system

- Touchscreen panel (DELTA 7”)

- Adjustable ram and pot stroke control

- Adjustable ram and pot tonnage (pressure) control

- Automatic lubrication system

- Electronic filter contamination warning

- Monitoring of hydraulic unit oil temperature and system status via display

- Cooling system

- Off-line filtration

- Safety systems for operator protection

- SIEMENS – SCHNEIDER switchgear components

📐 Technical Specifications – CHSP 150/50

Type: Steel construction, 8-guided H-frame press body

Frame Material: St52 – ERDEMİR

Slide Bearings: Bronze Zr14

Capacity (Ram): 150 Tons

Capacity (Pot): 50 Tons

Moving Table Size: 1000 × 1200 mm

Fixed Table Size: 1000 × 1200 mm

Parallelism Tolerance: 120 micron/m

Perpendicularity Tolerance: 60 micron/m

Stroke (Ram): 600 mm

Stroke (Pot): 200 mm

Min. Daylight: 100 mm

Max. Daylight: 700 mm

Weld Stress Relief: Vibratory stress relief

Welding Application: WPQR and WPS approved by TÜRK-AK, EN ISO 15614-1:2017 (Welding applications are supervised by certified “welding coordination engineers” in accordance with EN ISO 14731)

Max. Operating Pressure: 250 Bar

Total Motor Power: 18.5 kW – IE3

Main Pump: 32 cm³ – REXROTH or PARKER

Moving Table Fast Down Speed: 150 mm/s

Moving Table Drawing Speed: 12 mm/s

Moving Table Return Speed: 170 mm/s

Pot Table Forward Speed: 30 mm/s

Main Cylinder Inner Diameter: Ø280 mm – Ck45

Pot Cylinder Inner Diameter: Ø160 mm – Ck45

Auxiliary Accelerating Cylinders: 2 units

Approximate Height: 3650 mm

Approximate Width: 2950 mm

Approximate Depth: 2000 mm

Lower Table Height from Floor: 1250 mm

Pre-fill Valve: NG 100

Hydraulic Unit: REXROTH or PARKER

Cooling System: EMMEGI – CIESSE – PARKER

Off-line Filtration: REXROTH or PARKER

Linear Displacement Scale: NOVATECHNIK or TURCK

PLC System: DELTA

Touchscreen Panel: DELTA 7”

Switchgear: SIEMENS – SCHNEIDER

Psdpfxex N T U Ho Aaqjpl

Approximate Weight: 11 Tons

Manufacturing Note

This machine is produced by CRONOSSTECH in Turkey.

Annuncio economico

Turchia

Turchia

1.354 km

Pressa idraulica a doppia azione H tipo 100/40 tonnellate per imbutitura profonda

CRONOSSTECHCHSP 100/40

Chiama

Condizione: nuovo, Anno di produzione: 2025, forza di pressatura: 100 t, larghezza tavola: 1.000 mm, lunghezza del tavolo: 1.200 mm, forza di retrazione: 40 t, corsa: 600 mm, pressione di esercizio: 250 barra, Equipaggiamento: barriera di sicurezza a luce, documentazione / manuale, CRONOSSTECH CHSP 100/40

H-Type Hydraulic Deep Drawing (Spinning) Press – 8-Gibbed

General Description

The CRONOSSTECH CHSP series H-type hydraulic deep drawing presses are designed with a double-acting principle to ensure controlled material flow during sheet metal forming, deep drawing, and spinning applications. The 8-gibbed H-frame construction provides maximum rigidity throughout the pressing cycle, maintaining stable parallelism and perpendicularity tolerances along the stroke.

The CHSP 100/40 model, featuring a 100-ton main ram and a 40-ton cushion (pot) capacity, is engineered for precise deep drawing and spinning operations. The frame structure is stress-relieved by vibration methods to guarantee long-term durability and operational reliability.

⚙️ Standard Equipment

- Steel construction, 8-gibbed H-frame press body

- Stress-relieved frame by vibration

- Bronze Zr14 slide bearings

- WPQR and WPS certified welds accredited by TÜRK-AK (EN ISO 15614-1:2017 / EN ISO 14731)

- Design and manufacturing in accordance with CE standards

- PLC-controlled hydraulic system

- 7” DELTA touchscreen control panel

- Adjustable ram and cushion stroke control

- Adjustable ram and cushion tonnage (pressure) control

Ppodpfxox N T Uyo Aaqjl

- Automatic lubrication system

- Electronically monitored filter clogging alert

- Real-time display of hydraulic oil temperature and system status on the panel

- Cooling system

- Off-line filtration

- Safety systems for operator protection

- SIEMENS – SCHNEIDER switchgear components

📐 Technical Specifications – CHSP 100/40

- Type: Steel construction, 8-gibbed H-frame press body

- Frame Material: St52 – ERDEMİR

- Slide Bearings: Bronze Zr14

- Capacity (Ram): 100 Tons

- Capacity (Cushion): 40 Tons

- Moving Table Size: 1000 × 1200 mm

- Fixed Table Size: 1000 × 1200 mm

- Parallelism Tolerance: 120 micron/m

- Perpendicularity Tolerance: 60 micron/m

- Stroke (Ram): 600 mm

- Stroke (Cushion): 200 mm

- Min. Daylight Opening: 100 mm

- Max. Daylight Opening: 700 mm

- Weld Stress Relieving: Vibration stress relief

- Welding Application: WPQR and WPS approved by TÜRK-AK accreditation EN ISO 15614-1:2017 (Supervised by certified welding coordination engineers as per EN ISO 14731)

- Max. Working Pressure: 250 Bar

- Total Motor Power: 11 kW – IE3

- Main Pump: 22 cm³ – REXROTH or PARKER

- Moving Table Fast Approach Speed: 150 mm/s

- Moving Table Drawing Speed: 12 mm/s

- Moving Table Return Speed: 170 mm/s

- Cushion Table Advance Speed: 30 mm/s

- Main Cylinder Bore: Ø230 mm – Ck45

- Cushion Cylinder Bore: Ø140 mm – Ck45

- Auxiliary Acceleration Cylinders: 2 units

- Approximate Height: 3400 mm

- Approximate Width: 2950 mm

- Approximate Depth: 2000 mm

- Lower Table Height from Floor: 1250 mm

- Pre-Fill Valve: NG 100

- Hydraulic Power Unit: REXROTH or PARKER

- Cooling System: EMMEGI – CIESSE – PARKER

- Off-line Filtration: REXROTH or PARKER

- Linear Position Ruler: NOVATECHNIK or TURCK

- PLC Control: DELTA

- Touchscreen Panel: DELTA 7”

- Switchgear Components: SIEMENS – SCHNEIDER

- Approximate Weight: 9 Tons

Production Note

This machine is manufactured by CRONOSSTECH in Turkey.

Informati ora

+49 201 857 86 152

+49 201 857 86 152

Pubblica un annuncio ora

*per annuncio / mese

Annuncio economico

Turchia

Turchia

1.354 km

PRESSA IDRAULICA MONOAZIONE H-TYPE DA 2500 TON

CRONOSSTECHCHP 2500

Chiama

Condizione: nuovo, Anno di produzione: 2025, forza di pressatura: 2.500 t, larghezza tavola: 1.800 mm, lunghezza del tavolo: 2.600 mm, corsa: 1.000 mm, pressione di esercizio: 250 barra, Equipaggiamento: barriera di sicurezza a luce, documentazione / manuale, CRONOSSTECH CHP 2500

H-Type Hydraulic Press – 8 Guideways

General Description

The CRONOSSTECH CHP series H-type hydraulic presses are engineered for heavy forming, deep drawing, and metal spinning operations requiring very high tonnage. The 8-guideway H-frame structure guarantees maximum rigidity during pressing; parallelism and perpendicularity tolerances are consistently maintained throughout the extended stroke.

The CHP 2500 model, featuring large platen dimensions, a multi-cylinder main pressing system, and a high-capacity hydraulic unit, is designed for automotive, heavy industry, defense industry, and high-tonnage die applications. The frame construction is stress-relieved by vibration, ensuring long-lasting and reliable operation.

⚙️ Standard Equipment

- Steel construction, 8-guideway H-frame body type

- Vibration-stress relieved body structure

- Bronze Zr14 guide bushings

- WPQR and WPS certified welds accredited by TÜRK-AK (EN ISO 15614-1:2017 / EN ISO 14731)

- Design and manufacturing compliant with CE standards

- PLC-controlled hydraulic system

- 7” DELTA touchscreen panel

- Adjustable ram stroke and tonnage control

- Automatic lubrication system

- Electronic filter contamination alert

- Hydraulic unit oil temperature and system status display

- Cooling system

- Off-line filtration

Ppedpfsx N T S Eex Aaqol

- Safety systems for operator protection

- SIEMENS – SCHNEIDER switchgear components

📐 Technical Specifications – CHP 2500

Type: Steel construction, 8-guideway H-frame body

Frame Material: St52 – ERDEMİR

Guide Bushings: Bronze Zr14

Capacity (Ram): 2500 Ton

Moving Platen Size: 1800 × 2600 mm

Fixed Platen Size: 1800 × 2600 mm

Parallelism Tolerance: 120 micron/meter

Perpendicularity Tolerance: 60 micron/meter

Stroke (Ram): 1000 mm

Min. Daylight: 200 mm

Max. Daylight: 1200 mm

Weld Stress Relief: Via vibration

Welding: WPQR and WPS approved, TÜRK-AK accredited, EN ISO 15614-1/2017

Max. Operating Pressure: 250 Bar

Total Motor Power: 180 kW – IE3

Main Pump: 140 cm³ – REXROTH or PARKER

Moving Platen Fast Descent Speed: 150 mm/sec

Moving Platen Drawing Speed: 12 mm/sec

Moving Platen Return Speed: 170 mm/sec

Main Cylinder Bore: Ø565 mm – Ck45 (4 pieces)

Auxiliary Acceleration Cylinders: 2 pieces

Approx. Height: 6500 mm

Approx. Width: 3950 mm

Approx. Depth: 2600 mm

Lower Platen Height from Floor: 1500 mm

Pre-fill Valve: NG 200

Hydraulic Unit: REXROTH or PARKER

Cooling System: EMMEGI – CIESSE – PARKER

Off-line Filtration: REXROTH or PARKER

Linear Distance Transducer: NOVATECHNIK or TURCK

PLC Application: DELTA

Touch Screen Panel: DELTA 7”

Switchgear: SIEMENS – SCHNEIDER

Approx. Weight: 120 Ton

Production Note

This machine is manufactured by CRONOSSTECH in Turkey.

Annuncio economico

Turchia

Turchia

1.354 km

Pressa idraulica a semplice effetto tipo H da 2000 tonnellate

CRONOSSTECHCHP 2000

Chiama

Condizione: nuovo, Anno di produzione: 2025, forza di pressatura: 2.000 t, larghezza tavola: 1.500 mm, lunghezza del tavolo: 2.500 mm, corsa: 1.000 mm, pressione di esercizio: 250 barra, Equipaggiamento: barriera di sicurezza a luce, documentazione / manuale, CRONOSSTECH CHP 2000

H-Type Hydraulic Press – 8-Guided

General Description

The CRONOSSTECH CHP series H-type hydraulic presses are engineered for applications demanding extremely high tonnage, such as heavy-duty forming, deep drawing, spinning, and die operations. The 8-guide H-frame structure provides maximum stiffness during pressing and maintains parallelism and perpendicularity tolerances throughout the stroke.

The CHP 2000 model, with its large table dimensions, high-capacity hydraulic system, and robust motor configuration, offers a reliable and durable solution for the automotive, defense, heavy industry, and high-tonnage production lines. The frame is stress-relieved via vibration, ensuring stable operation.

⚙️ Standard Equipment

- Steel construction, 8-guided H-frame press body

- Stress-relieved frame by vibration

- Bronze Zr14 guide bushings

- WPQR and WPS certified welding applications accredited by TÜRK-AK (EN ISO 15614-1:2017 / EN ISO 14731)

- Design and manufacturing in accordance with CE standards

Ppodpfx Asx N T Sreaqol

- PLC-controlled hydraulic system

- Touchscreen panel (DELTA 7”)

- Adjustable ram stroke and tonnage control

- Automatic lubrication system

- Electronically monitored filter contamination warning

- On-screen monitoring of hydraulic oil temperature and system status

- Cooling system

- Off-line filtration

- Safety systems for operator protection

- SIEMENS – SCHNEIDER switchgear components

📐 Technical Specifications – CHP 2000

Type: Steel construction, 8-guided H-frame press body

Frame Material: St52 – ERDEMİR

Guide Bushings: Bronze Zr14

Capacity (Ram): 2000 Ton

Moving Table Dimensions: 1500 x 2500 mm

Fixed Table Dimensions: 1500 x 2500 mm

Parallelism Tolerance: 120 micron/meter

Perpendicularity Tolerance: 60 micron/meter

Stroke (Ram): 1000 mm

Min. Daylight: 200 mm

Max. Daylight: 1200 mm

Weld Stress Relief: Vibratory stress relief

Welding Application: WPQR and WPS certified, TÜRK-AK accredited – EN ISO 15614-1/2017

Max. Working Pressure: 250 Bar

Total Motor Power: 180 kW – IE3

Main Pump: 140 cm³ – REXROTH or PARKER

Moving Table Fast Descent Speed: 150 mm/s

Moving Table Drawing Speed: 12 mm/s

Moving Table Return Speed: 170 mm/s

Main Cylinder Inner Diameter: Ø720 mm – Ck45 (2 units)

Auxiliary Acceleration Cylinders: 2 units

Approx. Press Height: 6300 mm

Approx. Press Width: 3850 mm

Approx. Press Depth: 2500 mm

Lower Table Height from Floor: 1500 mm

Pre-fill Valve: NG 200

Hydraulic Unit: REXROTH or PARKER

Cooling System: EMMEGI – CIESSE – PARKER

Off-line Filtration: REXROTH or PARKER

Linear Position Transducer: NOVATECHNIK or TURCK

PLC Application: DELTA

Touchscreen Panel: DELTA 7”

Switchgear Components: SIEMENS – SCHNEIDER

Approximate Weight: 95 Ton

Production Note

This machine is manufactured by CRONOSSTECH in Turkey.

Annuncio economico

Turchia

Turchia

1.354 km

PRESSA IDRAULICA MONOAZIONE TIPO H DA 1500 TONNELLATE

CRONOSSTECHCHP 1500

Chiama

Condizione: nuovo, Anno di produzione: 2025, forza di pressatura: 1.500 t, larghezza tavola: 1.500 mm, lunghezza del tavolo: 2.400 mm, corsa: 1.000 mm, pressione di esercizio: 250 barra, Equipaggiamento: barriera di sicurezza a luce, documentazione / manuale, CRONOSSTECH CHP 1500

H-Type Hydraulic Deep Drawing Press – 8 Guides

General Description

The CRONOSSTECH CHP series H-type hydraulic deep drawing presses are designed for deep drawing, forming, and heavy-duty shaping applications that require high tonnage. The 8-guide H-frame structure provides maximum rigidity and stability during pressing, helping to maintain parallelism and perpendicularity tolerances.

The CHP 1500 model, with its large table dimensions, powerful hydraulic system, and high stroke capacity, offers a reliable solution for the automotive, defense, heavy metal forming, and industrial production lines. The frame structure is stress-relieved by vibration to ensure long life and stable operation.

⚙️ Standard Equipment

- Steel construction, H-frame press body with 8 guides

- Stress-relieved frame by vibration

- Bronze Zr14 slide bearings

- WPQR and WPS certified welding processes accredited by TÜRK-AK (EN ISO 15614-1:2017 / EN ISO 14731)

- Design and production according to CE standards

- PLC-controlled hydraulic system

- Touch panel display (DELTA 7”)

- Adjustable ram stroke and tonnage control

- Automatic lubrication system

- Electronic filter contamination warning

- Display of hydraulic unit oil temperature and system status on screen

- Cooling system

- Off-line filtration

- Safety systems for operator protection

- SIEMENS – SCHNEIDER electrical switchgear components

📐 Technical Specifications – CHP 1500

- Type: Steel construction, H-frame press body with 8 guides

- Frame Material: St52 – ERDEMİR

- Slide Bearing: Bronze Zr14

- Capacity (Ram): 1,500 Ton

- Movable Table Dimensions: 1,500 × 2,400 mm

- Fixed Table Dimensions: 1,500 × 2,400 mm

- Parallelism Tolerance: 120 micron/m

- Perpendicularity Tolerance: 60 micron/m

- Stroke (Ram): 1,000 mm

- Min. Daylight: 200 mm

- Max. Daylight: 1,200 mm

- Stress Relief: Vibration method

- Welding Certification: Welding application certified to EN ISO 15614-1/2017, WPQR and WPS, accredited by TÜRK-AK

- Max. Working Pressure: 250 Bar

- Total Motor Power: 90 kW – IE3

- Main Pump: 101 cm³ – REXROTH or PARKER

- Movable Table Fast Descent Speed: 150 mm/sec

- Movable Table Drawing Speed: 12 mm/sec

- Movable Table Return Speed: 170 mm/sec

- Main Cylinder Bore: Ø620 mm – Ck45 (2 units)

- Auxiliary Acceleration Cylinders: 2 units

- Approximate Height of Press: 6,250 mm

- Approximate Width of Press: 3,750 mm

- Approximate Depth of Press: 2,500 mm

- Lower Table Height from Floor: 1,500 mm

- Pre-fill Valve: NG 200

- Hydraulic Unit: REXROTH or PARKER

- Cooling System: EMMEGI – CIESSE – PARKER

- Off-line Filtration: REXROTH or PARKER

- Linear Measurement Scale: NOVATECHNIK or TURCK

- PLC Application: DELTA

- Touch Panel Display: DELTA 7”

- Switchgear Components: SIEMENS – SCHNEIDER

- Approximate Weight: 70 Ton

Ppedex N T R Uspfx Aaqjl

Production Note

This machine is manufactured by CRONOSSTECH in Turkey.

Annuncio economico

Turchia

Turchia

1.354 km

PRESSA IDRAULICA MONOAZIONE TIPO H DA 1200 TON

CRONOSSTECHCHP 1200

Chiama

Condizione: nuovo, Anno di produzione: 2025, forza di pressatura: 1.200 t, larghezza tavola: 1.500 mm, lunghezza del tavolo: 2.000 mm, corsa: 1.000 mm, pressione di esercizio: 250 barra, Equipaggiamento: barriera di sicurezza a luce, documentazione / manuale, CRONOSSTECH CHP 1200

H-Type Hydraulic Deep Drawing Press – 8-Guideway

General Description

The CRONOSSTECH CHP series H-type hydraulic deep drawing presses are specifically designed for deep drawing, forming, shaping, and heavy-duty pressing applications. With an 8-guideway H-frame structure, it provides maximum rigidity, stability, and precision under high tonnage. The CHP 1200 model offers reliable and long-lasting performance for industrial production lines requiring high force.

The frame is stress-relieved by vibration, ensuring even distribution of loads during pressing and maintaining parallelism and perpendicularity tolerances.

⚙️ Standard Equipment

Steel construction, 8-guideway H-frame press body

Vibration stress-relieved frame structure

Bronze Zr14 slideway bearings

WPQR and WPS welding applications approved by TÜRK-AK accreditation (EN ISO 15614-1:2017 / EN ISO 14731)

Design and production according to CE standards

PLC-controlled hydraulic system

Touchscreen panel (DELTA 7”)

Adjustable ram stroke and tonnage control

Automatic lubrication system

Electronic filter contamination warning

On-screen monitoring of hydraulic unit oil temperature and system status

Cooling system

Off-line filtration

Safety systems for operator protection

SIEMENS – SCHNEIDER switchgear components

📐 Technical Specifications – CHP 1200

Type: Steel construction, 8-guideway H-frame press body

Frame Material: St52 – ERDEMİR

Slideway Bearings: Bronze Zr14

Capacity (Ram): 1200 Tons

Moving Table Size: 1500 × 2000 mm

Fixed Table Size: 1500 × 2000 mm

Parallelism Tolerance: 120 micron/meter

Perpendicularity Tolerance: 60 micron/meter

Stroke (Ram): 1000 mm

Min. Clearance: 100 mm

Max. Clearance: 1100 mm

Stress Relief: Vibration stress relief

Welding Application: EN ISO 15614-1/2017 certified, WPQR & WPS approved by TÜRK-AK

Max. Working Pressure: 250 Bar

Total Motor Power: 75 kW – IE3

Main Pump: 70 cm³ – REXROTH or PARKER

Moving Table Fast Down Speed: 150 mm/sec

Moving Table Drawing Speed: 12 mm/sec

Moving Table Return Speed: 170 mm/sec

Main Cylinder Bore: Ø560 mm – Ck45 (2 units)

Auxiliary Acceleration Cylinders: 2 units

Approx. Height of the Press: 6100 mm

Approx. Width of the Press: 3550 mm

Approx. Depth of the Press: 2400 mm

Distance from Floor to Bottom Table: 1450 mm

Pre-fill Valve: NG 200

Hydraulic Unit: REXROTH or PARKER

Cooling System: EMMEGI – CIESSE – PARKER

Off-line Filtration: REXROTH or PARKER

Linear Position Sensor: NOVATECHNIK or TURCK

PLC Application: DELTA

Touchscreen Panel: DELTA 7”

Switchgear Components: SIEMENS – SCHNEIDER

Psdpfxox N T Rus Aaqopl

Approximate Weight: 60 Tons

Production Note

This machine is manufactured by CRONOSSTECH in Turkey.

Annuncio economico

Turchia

Turchia

1.354 km

Pressa idraulica H tipo 1000 ton singolo effetto

CRONOSSTECHCHP 1000

Chiama

Condizione: nuovo, Anno di produzione: 2025, forza di pressatura: 1.000 t, larghezza tavola: 1.500 mm, lunghezza del tavolo: 2.000 mm, corsa: 1.000 mm, pressione di esercizio: 250 barra, Equipaggiamento: barriera di sicurezza a luce, documentazione / manuale, CRONOSSTECH CHP 1000

H-Type Single-Acting Hydraulic Press – 8-Guided Slides

General Description

The CRONOSSTECH CHP series H-type single-acting hydraulic presses are engineered for sheet metal forming, deep drawing, straightening, and heavy-duty pressing applications requiring high tonnage. The 8-guide H-frame structure ensures maximum rigidity, precision, and long service life by evenly distributing the immense forces generated during pressing. The CHP 1000 model has been developed to provide reliable and stable performance for heavy industry production lines.

CHP Series – Structural Features

CHP series presses are designed considering heavy industrial conditions. The frame and main supporting structures are stress relieved through vibration methods. Smooth load distribution and high accuracy along the slide travel are achieved by bronze Zr14 slide bearings.

⚙️ Standard Equipment

- Steel construction, 8-guide H-type press frame

- Stress-relieved body via vibration method

- Bronze Zr14 slide bearings

- Welding applications certified by WPQR & WPS, accredited by TÜRK-AK (EN ISO 15614-1:2017 / EN ISO 14731)

- Design and manufacturing in compliance with CE standards

- PLC-controlled hydraulic system

- 7” DELTA touchscreen panel

- Adjustable ram stroke and tonnage control

- Automatic lubrication system

- Electronically controlled filter contamination warning

- On-screen monitoring of hydraulic unit oil temperature and system status

- Cooling system

- Off-line filtration

- Two-hand control system

- Light curtain (standard for operator safety)

- SIEMENS – SCHNEIDER switchgear components

📐 Technical Specifications – CHP 1000

- Type: Steel construction, 8-slide H-frame press type

- Frame Material: St52 – ERDEMİR

- Slide Bearing: Bronze Zr14

- Capacity (Ram): 1000 Tons

- Movable Table Dimensions: 1500 × 2000 mm

Ppsdpfx Aaex N T Rboqsl

- Fixed Table Dimensions: 1500 × 2000 mm

- Parallelism Tolerance: 120 micron/m

- Squareness Tolerance: 60 micron/m

- Stroke (Ram): 1000 mm

- Min. Daylight: 100 mm

- Max. Daylight: 1100 mm

- Stress Relief: Vibration method

- Welding Application: WPQR and WPS certified, accredited by TÜRK-AK, EN ISO 15614-1:2017

- Max. Working Pressure: 250 Bar

- Total Motor Power: 75 kW – IE3

- Main Pump: 70 cm³ – REXROTH or PARKER

- Movable Table Rapid Descend Speed: 150 mm/s

- Movable Table Pressing Speed: 12 mm/s

- Movable Table Return Speed: 170 mm/s

- Main Cylinder Bore Diameter: Ø500 mm – Ck45 (2 units)

- Auxiliary Acceleration Cylinders: 2 units

- Approx. Press Height: 6000 mm

- Approx. Press Width: 3450 mm

- Approx. Press Depth: 2400 mm

- Lower Table Height from Floor: 1450 mm

- Pre-fill Valve: NG 200

- Hydraulic Unit: REXROTH or PARKER

- Cooling System: EMMEGI – CIESSE – PARKER

- Off-line Filtration: REXROTH or PARKER

- Linear Position Transducer: NOVATECHNIK or TURCK

- PLC System: DELTA

- Touchscreen Panel: DELTA 7”

- Switchgear Components: SIEMENS – SCHNEIDER

- Approx. Weight: 55 Tons

Production Note

This machine is manufactured by CRONOSSTECH in Turkey.

Annuncio economico

Turchia

Turchia

1.354 km

PRESSA IDRAULICA MONOAZIONE TIPO H 800 TON

CRONOSSTECHCHP 800

Chiama

Condizione: nuovo, Anno di produzione: 2025, forza di pressatura: 800 t, larghezza tavola: 1.500 mm, lunghezza del tavolo: 2.000 mm, corsa: 800 mm, pressione di esercizio: 250 barra, Equipaggiamento: barriera di sicurezza a luce, documentazione / manuale, CRONOSSTECH CHP 800

H-Type Single-Acting Hydraulic Press – 8 Slideways

General Description

The CRONOSSTECH CHP series H-type single-acting hydraulic presses are designed for heavy-duty sheet metal forming, straightening, assembly, and high-tonnage pressing applications. The 8-slideway H-frame structure ensures even distribution of the high forces generated during pressing, providing maximum rigidity and extended service life. The CHP 800 model has been developed for high-capacity production lines, aiming for dependable and stable performance.

CHP Series – Structural Features

The CHP series presses are engineered taking into account heavy industry conditions. The frame and main load-bearing components are stress-relieved through vibration. The bronze Zr14 slideway bearings ensure uniform load distribution and precise operation throughout the ram movement.

⚙️ Standard Equipment

- Steel construction, H-type press frame with 8 slideways

- Vibration stress-relieved frame structure

- Bronze Zr14 slideway bearings

- WPQR & WPS certified welding applications accredited by TÜRK-AK (EN ISO 15614-1:2017 / EN ISO 14731)

- Design and manufacturing in accordance with CE standards

- PLC-controlled hydraulic system

- Touchscreen control panel (DELTA 7”)

- Adjustable ram stroke and tonnage control

- Automatic lubrication system

- Electronic filter contamination warning

- On-screen monitoring of hydraulic unit oil temperature and system status

- Cooling system

- Off-line filtration

- Two-hand control system

- Light curtain (operator safety standard)

- SIEMENS – SCHNEIDER switching components

📐 Technical Specifications – CHP 800

- Type: Steel construction, H-frame with 8 slideways

- Frame Material: St52 – ERDEMİR

- Slideway Bearings: Bronze Zr14

- Capacity (Ram): 800 Tons

- Moving Table Size: 1500 × 2000 mm

Ppedpfex N T Nksx Aaqol

- Fixed Table Size: 1500 × 2000 mm

- Parallelism Tolerance: 120 micron/m

- Verticality Tolerance: 60 micron/m

- Stroke (Ram): 800 mm

- Min. Daylight: 100 mm

- Max. Daylight: 900 mm

- Stress Relief: Via vibration

- Welding Application: WPQR and WPS certified by TÜRK-AK, welding application certificate per EN ISO 15614-1/2017 (supervised by certified welding coordination engineers per EN ISO 14731)

- Max. Operating Pressure: 250 Bar

- Total Motor Power: 75 kW – IE3

- Main Pump: 70 cm³ – REXROTH or PARKER

- Moving Table Fast Descent Speed: 150 mm/sec

- Moving Table Drawing Speed: 12 mm/sec

- Moving Table Return Speed: 170 mm/sec

- Main Cylinder Inner Diameter: Ø390 mm – Ck45 (2 units)

- Auxiliary Acceleration Cylinders: 2 units

- Approximate Press Height: 6000 mm

- Approximate Press Width: 3350 mm

- Approximate Press Depth: 2700 mm

- Bottom Table Height from Floor: 1450 mm

- Pre-Fill Valve: NG 200

- Hydraulic Unit: REXROTH or PARKER

- Cooling System: EMMEGI – CIESSE – PARKER

- Off-line Filtration: REXROTH or PARKER

- Linear Position Scale: NOVATECHNIK or TURCK

- PLC Application: DELTA

- Touchscreen Panel: DELTA 7”

- Switching Components: SIEMENS – SCHNEIDER

- Approximate Weight: 45 Tons

Production Note

This machine is manufactured in Turkey by CRONOSSTECH.

Annuncio economico

Turchia

Turchia

1.354 km

PRESSA IDRAULICA MONOAZIONE 600 TON TIPO H

CRONOSSTECHCHP 600

Chiama

Condizione: nuovo, Anno di produzione: 2025, forza di pressatura: 600 t, larghezza tavola: 1.200 mm, lunghezza del tavolo: 1.500 mm, corsa: 800 mm, pressione di esercizio: 250 barra, Equipaggiamento: barriera di sicurezza a luce, documentazione / manuale, CRONOSSTECH CHP 600

H-Type Single-Acting Hydraulic Press – 8-Guided

General Description

The CRONOSSTECH CHP series H-type single-acting hydraulic presses are high-rigidity industrial machines developed for metal sheet forming, straightening, assembly, and heavy-duty pressing applications. The 8-guide H-frame design ensures balanced distribution of high forces generated during pressing, providing long-lasting and stable operation. The CHP 600 model is engineered for reliable performance in production processes requiring high tonnage.

CHP Series – Structural Features

CHP series presses are designed with heavy-duty conditions in mind. The frame and load-bearing components are stress-relieved by vibration. Bronze Zr14 slide bearings offer uniform load distribution and high precision throughout the ram movement.

⚙️ Standard Equipment

- Steel construction, 8-guide H-type press frame

- Stress-relieved body structure by vibration

- Bronze Zr14 slide bearings

- WPQR & WPS certified welding applications with TÜRK-AK accreditation (EN ISO 15614-1:2017 / EN ISO 14731)

- Design and manufacturing in accordance with CE standards

- PLC-controlled hydraulic system

- Touchscreen panel (DELTA 7”)

- Adjustable ram stroke and tonnage control

- Automatic lubrication system

- Electronic filter contamination warning

- Display of hydraulic unit oil temperature and system status on screen

- Cooling system

- Off-line filtration

- Two-hand control system

- Light curtain (standard for operator safety)

- SIEMENS – SCHNEIDER switching components

📐 Technical Specifications – CHP 600

Psdsx N T Iaspfx Aaqspl

Type: Steel construction, 8-guide H-frame press

Frame Material: St52 – ERDEMİR

Slide Bearings: Bronze Zr14

Capacity (Ram): 600 Tons

Movable Table Size: 1200 × 1500 mm

Fixed Table Size: 1200 × 1500 mm

Parallelism Tolerance: 120 micron/m

Perpendicularity Tolerance: 60 micron/m

Stroke (Ram): 800 mm

Min. Daylight: 100 mm

Max. Daylight: 900 mm

Weld Stress Relief: By vibration

Welding Application: TÜRK-AK accredited WPQR & WPS certified according to EN ISO 15614-1/2017 (supervised by certified welding coordination engineers in accordance with EN ISO 14731)

Max. Operating Pressure: 250 Bar

Total Motor Power: 55 kW – IE3

Main Pump: 70 cm³ – REXROTH or PARKER

Movable Table Fast Down Speed: 150 mm/s

Movable Table Pressing Speed: 12 mm/s

Movable Table Return Speed: 170 mm/s

Main Cylinder Bore: Ø550 mm – Ck45

Pot Cylinder Bore: Ø320 mm – Ck45

Auxiliary Acceleration Cylinders: 2 pcs

Approximate Machine Height: 5900 mm

Approximate Machine Width: 3250 mm

Approximate Machine Depth: 2300 mm

Lower Table Height from Floor: 1400 mm

Pre-fill Valve: NG 150

Hydraulic Unit: REXROTH or PARKER

Cooling System: EMMEGI – CIESSE – PARKER

Off-line Filtration: REXROTH or PARKER

Linear Displacement Scale: NOVATECHNIK or TURCK

PLC Application: DELTA

Touchscreen Panel: DELTA 7”

Switching Components: SIEMENS – SCHNEIDER

Approximate Weight: 28 Tons

Production Note

This machine is manufactured by CRONOSSTECH in Turkey.

Annuncio economico

Turchia

Turchia

1.354 km

PRESSA IDRAULICA MONOAZIONE TIPO H DA 500 TON

CRONOSSTECHCHP 500

Chiama

Condizione: nuovo, Anno di produzione: 2025, forza di pressatura: 500 t, larghezza tavola: 1.200 mm, lunghezza del tavolo: 1.500 mm, corsa: 1.000 mm, pressione di esercizio: 250 barra, Equipaggiamento: barriera di sicurezza a luce, documentazione / manuale, CRONOSSTECH CHP 500

H-Type Single-Acting Hydraulic Press – 8-Guided Slides

General Description

The CRONOSSTECH CHP series H-type single-acting hydraulic presses are high-rigidity industrial press solutions developed for sheet metal forming, straightening, assembly, and die pressing applications. The 8-guide H-frame design ensures a balanced distribution of high loads during pressing, providing stable and repeatable operation. The CHP 500 model is engineered for heavy-duty production processes that require high tonnage, with a focus on long-lasting and reliable performance.

CHP Series – Structural Features

CHP series presses are designed with heavy-duty operating conditions in mind. The frame and support components are stress-relieved by vibration. Bronze Zr14 slide bushings guarantee even load distribution and sustained precision throughout the ram stroke.

⚙️ Standard Equipment

- Steel construction, H-type press frame with 8 guided slides

- Stress-relieved frame and supporting components (via vibration)

- Bronze Zr14 slide bushings

- WPQR & WPS certified welding procedures approved by TÜRK-AK accreditation (EN ISO 15614-1:2017 / EN ISO 14731)

- Machine design and manufacture conforming to CE standards

- PLC-controlled hydraulic system

- 7” DELTA touchscreen panel

- Adjustable ram stroke and tonnage control

- Automatic lubrication system

- Electronically monitored filter contamination alert

Ppjdpox N T H Ajfx Aaqjl

- Hydraulic unit oil temperature and system status monitoring on display

- Cooling system

- Off-line filtration

- Two-hand control system

- Light curtain (standard for operator safety)

- SIEMENS – SCHNEIDER electrical components

📐 Technical Specifications – CHP 500

- Type: Steel construction, H-frame press type with 8 guided slides

- Frame Material: St52 – ERDEMİR

- Slide Bushings: Bronze Zr14

- Capacity (Ram): 500 Tons

- Moving Table Size: 1200 × 1500 mm

- Fixed Table Size: 1200 × 1500 mm

- Parallelism Tolerance: 120 micron/meter

- Perpendicularity Tolerance: 60 micron/meter

- Stroke (Ram): 1000 mm

- Min. Clearance: 100 mm

- Max. Clearance: 1100 mm

- Weld Stress Relief: Vibration method

- Welding Application: WPQR and WPS certified by TÜRK-AK (EN ISO 15614-1:2017), monitored by certified welding coordination engineers in accordance with EN ISO 14731

- Max. Operating Pressure: 250 Bar

- Total Motor Power: 45 kW – IE3

- Main Pump: 70 cm³ – REXROTH or PARKER

- Moving Table Rapid Descent Speed: 150 mm/sec

- Moving Table Drawing Speed: 12 mm/sec

- Moving Table Return Speed: 170 mm/sec

- Main Cylinder Inner Diameter: Ø500 mm – Ck45

- Auxiliary Acceleration Cylinders: 2 units

- Approximate Press Height: 5800 mm

- Approximate Press Width: 3250 mm

- Approximate Press Depth: 2200 mm

- Lower Table Height from Floor: 1400 mm

- Pre-Fill Valve: NG 150

- Hydraulic Unit: REXROTH or PARKER

- Cooling System: EMMEGI – CIESSE – PARKER

- Off-line Filtration: REXROTH or PARKER

- Linear Position Measuring Scale: NOVATECHNIK or TURCK

- PLC Application: DELTA

- Touchscreen Panel: DELTA 7”

- Electrical Components: SIEMENS – SCHNEIDER

- Approximate Weight: 23 Tons

Production Note

This machine is manufactured in Turkey by CRONOSSTECH.

Annuncio economico

Turchia

Turchia

1.354 km

PRESSA IDRAULICA MONOAZIONE TIPO H DA 400 TON

CRONOSSTECHCHP 400

Chiama

Condizione: nuovo, Anno di produzione: 2025, forza di pressatura: 400 t, larghezza tavola: 1.200 mm, lunghezza del tavolo: 1.500 mm, corsa: 800 mm, pressione di esercizio: 250 barra, Equipaggiamento: barriera di sicurezza a luce, documentazione / manuale, CRONOSSTECH CHP 400

Ppsdpfxox N T Hpe Aaqel

H-Type Single Acting Hydraulic Press – 8 Guideways

General Description

The CRONOSSTECH CHP series H-type single acting hydraulic presses are industrial press solutions featuring high rigidity, developed for sheet metal forming, straightening, assembly, and die pressing applications. Thanks to its 8-guide H-frame structure, high loads generated during pressing are distributed evenly, delivering stable and repeatable operation. The CHP 400 model is designed for reliable and long-lasting performance in heavy-duty applications requiring high tonnage.

CHP Series – Structural Features

The CHP series presses are engineered with consideration for heavy-duty operating conditions. Frame and supporting elements are stress-relieved by vibration. Bronze Zr14 slide bearings deliver smooth force distribution during ram movement and help maintain long-term precision.

⚙️ Standard Equipment

- Steel construction, 8-guideway H-type press frame

- Vibratory stress-relieved frame and support components

- Bronze Zr14 slide bearings

- Welding applications with TÜRK-AK accredited WPQR & WPS approval (EN ISO 15614-1:2017 / EN ISO 14731)

- Machine design and production in compliance with CE standards

- PLC-controlled hydraulic system

- Touch screen panel (DELTA 7”)

- Adjustable ram stroke and tonnage control

- Automatic lubrication system

- Electronic filter contamination alert

- On-screen monitoring of hydraulic unit oil temperature and system status

- Cooling system

- Off-line filtration

- Two-hand control system

- Light barrier (standard for operator safety)

- SIEMENS – SCHNEIDER switchgear

📐 Technical Specifications – CHP 400

Type: Steel construction, 8-guide H-frame structure

Frame Material: St52 – ERDEMİR

Slide Bearings: Bronze Zr14

Capacity (Ram): 400 Ton

Movable Table Size: 1200 × 1500 mm

Fixed Table Size: 1200 × 1500 mm

Parallelism Tolerance: 120 micron/meter

Perpendicularity Tolerance: 60 micron/meter

Stroke (Ram): 800 mm

Min. Die Opening: 100 mm

Max. Die Opening: 900 mm

Weld Stress Relief: Vibratory stress-relieving

Welding Application: Welding procedures approved by TÜRK-AK accredited WPQR and WPS certificate to EN ISO 15614-1/2017, supervised by certified welding coordination engineers per EN ISO 14731

Max. Working Pressure: 250 Bar

Total Motor Power: 37 kW – IE3

Main Pump: 45 cm³ – REXROTH or PARKER

Movable Table Fast Descent Speed: 150 mm/sec

Movable Table Pressing Speed: 12 mm/sec

Movable Table Return Speed: 170 mm/sec

Main Cylinder Inner Diameter: Ø450 mm – Ck45

Auxiliary Acceleration Cylinders: 2 units

Approx. Press Height: 5600 mm

Approx. Press Width: 3250 mm

Approx. Press Depth: 2200 mm

Lower Table Height from Floor: 1400 mm

Pre-fill Valve: NG 150

Hydraulic Unit: REXROTH or PARKER

Cooling System: EMMEGI – CIESSE – PARKER

Off-line Filtration: REXROTH or PARKER

Linear Position Sensor: NOVATECHNIK or TURCK

PLC: DELTA

Touch Screen Panel: DELTA 7”

Switchgear: SIEMENS – SCHNEIDER

Approximate Weight: 19.5 Ton

Production Note

This machine is manufactured by CRONOSSTECH in Turkey.

Annuncio economico

Turchia

Turchia

1.354 km

PRESSA IDRAULICA MONOEFFETTO 300 TON TIPO H

CRONOSSTECHCHP 300

Chiama

Condizione: nuovo, Anno di produzione: 2025, forza di pressatura: 300 t, larghezza tavola: 1.000 mm, lunghezza del tavolo: 1.200 mm, corsa: 600 mm, pressione di esercizio: 250 barra, Equipaggiamento: barriera di sicurezza a luce, documentazione / manuale, CRONOSSTECH CHP 300

H-Type Single-Acting Hydraulic Press – 8 Guideways

General Description

The CRONOSSTECH CHP series H-type single-acting hydraulic presses are high-rigidity, industrial solutions developed for sheet metal forming, straightening, assembly, and die pressing applications. With its 8-guideway H-frame structure, the high loads generated during pressing are evenly distributed, ensuring stable and repeatable operation. The CHP 300 model is designed for medium to high tonnage production processes, delivering a long service life and reliable performance.

CHP Series – Structural Features

CHP series presses are engineered for heavy-duty operation. The frame and supporting components are stress-relieved using vibration. Bronze Zr14 slide bearings ensure uniform load distribution during ram movement, contributing to long-term precision.

⚙️ Standard Equipment

Steel-constructed, 8-guideway H-type press frame

Stress-relieved frame and supporting parts by vibration

Bronze Zr14 slide bearings

WPQR & WPS welding applications approved by TÜRK-AK accreditation

(EN ISO 15614-1:2017 / EN ISO 14731)

Machine structure designed and manufactured in compliance with CE standards

PLC-controlled hydraulic system

Touch panel display (DELTA 7”)

Adjustable ram stroke and tonnage control

Automatic lubrication system

Electronic filter contamination warning

On-screen monitoring of hydraulic unit oil temperature and system status

Cooling system

Off-line filtration

Two-hand control system

Light curtain (operator safety as standard)

SIEMENS – SCHNEIDER switchgear components

📐 Technical Specifications – CHP 300

Type: Steel construction, 8-guideway H-frame type

Frame Material: St52 – ERDEMİR

Slide Bearings: Bronze Zr14

Capacity (Ram): 300 Tons

Movable Table Size: 1000 × 1200 mm

Fixed Table Size: 1000 × 1200 mm

Parallelism Tolerance: 120 micron/m

Perpendicularity Tolerance: 60 micron/m

Stroke (Ram): 600 mm

Min. Daylight: 100 mm

Max. Daylight: 700 mm

Stress Relieving: Vibration method

Welding Application: WPQR and WPS certified by TÜRK-AK accreditation with EN ISO 15614-1/2017 welding procedure qualification certificate (monitored by certified welding coordination engineers as per EN ISO 14731)

Max. Operating Pressure: 250 Bar

Total Motor Power: 37 kW – IE3

Main Pump: 45 cm³ – REXROTH or PARKER

Movable Table Rapid Descent Speed: 150 mm/s

Movable Table Drawing Speed: 12 mm/s

Movable Table Return Speed: 170 mm/s

Main Cylinder Inner Diameter: Ø390 mm – Ck45

Auxiliary Acceleration Cylinders: 2 units

Approx. Height of Press: 4400 mm

Approx. Width of Press: 3250 mm

Approx. Depth of Press: 2200 mm

Lower Table Height from Floor: 1350 mm

Pre-fill Valve: NG 150

Hydraulic Unit: REXROTH or PARKER

Cooling System: EMMEGI – CIESSE – PARKER

Off-line Filtration: REXROTH or PARKER

Linear Position Sensor: NOVATECHNIK or TURCK

PLC Application: DELTA

Touch Panel Display: DELTA 7”

Switchgear Components: SIEMENS – SCHNEIDER

Approximate Weight: 10.5 Tons

Production Note

This machine is manufactured by CRONOSSTECH in Turkey.

Pjdjx N T E Eopfx Aaqspl

Annuncio economico

Turchia

Turchia

1.354 km

Pressa Idraulica Monoeffetto Tipo H da 250 Ton

CRONOSSTECHCHP 250

Chiama

Condizione: nuovo, Anno di produzione: 2025, forza di pressatura: 250 t, larghezza tavola: 1.000 mm, lunghezza del tavolo: 1.200 mm, corsa: 600 mm, pressione di esercizio: 250 barra, Equipaggiamento: barriera di sicurezza a luce, documentazione / manuale, CRONOSSTECH CHP 250

H-Type Single-Acting Hydraulic Press – 8-Guided

General Description

The CRONOSSTECH CHP series H-type single-acting hydraulic presses are robust industrial press solutions developed for sheet metal forming, straightening, assembly, and die stamping applications. Thanks to their 8-guided H-frame construction, loads generated during pressing are evenly distributed, providing stable and repeatable operation. The CHP 250 model is designed for production processes requiring medium to high tonnage, offering long-lasting and reliable performance.

CHP Series – Structural Features

CHP series presses are engineered for demanding heavy-duty operations. The frame and bearing parts are stress-relieved by vibration. Bronze Zr14 slide bearings ensure even load distribution during ram movement, contributing to prolonged high-precision operation.

⚙️ Standard Equipment

• Steel construction, 8-guide H-type press frame

• Vibration stress-relieved frame and carrier parts

• Bronze Zr14 slide bearings

• WPQR & WPS welding applications approved and accredited by TÜRK-AK (EN ISO 15614-1:2017 / EN ISO 14731)

• Machine design and production compliant with CE standards

• PLC-controlled hydraulic system

• Touchscreen control panel (DELTA 7”)

• Adjustable ram stroke and tonnage control

• Automatic lubrication system

• Electronic filter contamination warning

• Hydraulic unit oil temperature and system status monitoring via display

• Cooling system

• Off-line filtration

• Dual-hand control system

• Light curtain (standard operator safety)

• SIEMENS – SCHNEIDER switching components

📐 Technical Specifications – CHP 250

Type: Steel construction, 8-guided H-frame press

Frame Material: St52 – ERDEMİR

Guide Bearings: Bronze Zr14

Press Capacity (Ram): 250 Tons

Moving Table Size: 1000 × 1200 mm

Fixed Table Size: 1000 × 1200 mm

Parallelism Tolerance: 120 microns/m

Squareness Tolerance: 60 microns/m

Stroke (Ram): 600 mm

Min. Daylight: 100 mm

Max. Daylight: 700 mm

Weld Stress Relief: Vibration stress relief

Welding Application: WPQR and WPS approved welding application certified to EN ISO 15614-1/2017, accredited by TÜRK-AK (supervised by certified welding coordination engineers in accordance with EN ISO 14731)

Max. Operating Pressure: 250 Bar

Total Motor Power: 37 kW – IE3

Main Pump: 45 cm³ – REXROTH or PARKER

Rapid Descent Speed of Moving Table: 150 mm/s

Podpfxsx N T Els Aaqjpl

Pressing Speed of Moving Table: 12 mm/s

Return Speed of Moving Table: 170 mm/s

Main Cylinder Bore Diameter: Ø360 mm – Ck45

Auxiliary Boost Cylinders: 2 pcs

Approx. Height: 4200 mm

Approx. Width: 3250 mm

Approx. Depth: 2200 mm

Lower Table Height from Floor: 1350 mm

Pre-Fill Valve: NG 125

Hydraulic Power Unit: REXROTH or PARKER

Cooling System: EMMEGI – CIESSE – PARKER

Off-line Filtration: REXROTH or PARKER

Linear Distance Encoder: NOVATECHNIK or TURCK

PLC Application: DELTA

Touchscreen Display: DELTA 7”

Switching Components: SIEMENS – SCHNEIDER

Approximate Weight: 9.5 Tons

Production Note

This machine is manufactured by CRONOSSTECH in Turkey.

Annuncio economico

Turchia

Turchia

1.354 km

PRESSA IDRAULICA MONOAZIONE H-TYPE 200 TON

CRONOSSTECHCHP 200

Chiama

Condizione: nuovo, Anno di produzione: 2025, forza di pressatura: 200 t, larghezza tavola: 800 mm, lunghezza del tavolo: 1.000 mm, corsa: 600 mm, pressione di esercizio: 250 barra, Equipaggiamento: barriera di sicurezza a luce, documentazione / manuale, CRONOSSTECH CHP 200

H-Type Single-Acting Hydraulic Press – 8-Guideway

General Description

The CRONOSSTECH CHP series H-type single-acting hydraulic presses are industrial press solutions with high rigidity, developed for sheet metal forming, straightening, assembly, and die pressing applications. Thanks to its 8-guideway H-frame structure, loads generated during pressing are evenly distributed, ensuring stable and repeatable operation. The CHP 200 model is designed for applications requiring medium to high tonnage, offering reliable performance and long service life.

CHP Series – Structural Features

CHP series presses are engineered for heavy-duty operations. The frame and supporting components are stress-relieved using vibration methods. Bronze Zr14 guide bushings ensure smooth ram movement and long-term precision.

⚙️ Standard Equipment

- Steel construction, H-frame press body with 8 guideways

- Vibration stress-relieved frame and supporting components

- Bronze Zr14 guide bushings

- WPQR & WPS certified welded assemblies with TÜRK-AK accreditation (EN ISO 15614-1:2017 / EN ISO 14731)

- Machine structure designed and manufactured in compliance with CE standards

- PLC-controlled hydraulic system

- Touchscreen panel (DELTA 7”)

- Adjustable ram stroke and tonnage control

- Automatic lubrication system

- Electronic filter contamination warning system

- On-screen monitoring of hydraulic unit oil temperature and system status

- Cooling system

- Off-line filtration

- Dual-hand control system

- Light curtain (standard for operator safety)

- SIEMENS – SCHNEIDER switchgear components

📐 Technical Specifications – CHP 200

Type: Steel construction, H-frame with 8 guideways

Frame Material: St52 – ERDEMİR

Guide Bushings: Bronze Zr14

Capacity (Ram): 200 Tons

Moving Table Dimensions: 800 × 1000 mm

Fixed Table Dimensions: 800 × 1000 mm

Parallelism Tolerance: 120 micron/m.

Perpendicularity Tolerance: 60 micron/m.

Ram Stroke: 600 mm

Min. Daylight: 100 mm

Max. Daylight: 700 mm

Stress Relieving: Vibration method

Welding Application: WPQR and WPS certified welding application accredited by TÜRK-AK, compliant with EN ISO 15614-1/2017 (monitored by certified welding coordination engineers according to EN ISO 14731)

Max. Operating Pressure: 250 Bar

Total Motor Power: 22 kW – IE3

Main Pump: 32 cm³ – REXROTH or PARKER

Fast Down Speed (Moving Table): 150 mm/s

Pressing Speed (Moving Table): 12 mm/s

Return Speed (Moving Table): 170 mm/s

Main Cylinder Bore: Ø320 mm – Ck45

Auxiliary Acceleration Cylinders: 2 units

Approx. Height: 3800 mm

Approx. Width: 2950 mm

Approx. Depth: 2200 mm

Ppsdpfx Aex N T D Ueaqsl

Distance from Floor to Lower Table: 1350 mm

Pre-fill Valve: NG 125

Hydraulic Unit: REXROTH or PARKER

Cooling System: EMMEGI – CIESSE – PARKER

Off-line Filtration: REXROTH or PARKER

Linear Position Encoder: NOVATECHNIK or TURCK

PLC System: DELTA

Touchscreen Panel: DELTA 7”

Switchgear Components: SIEMENS – SCHNEIDER

Approximate Weight: 8 Tons

Production Note

This machine is manufactured by CRONOSSTECH in Turkey.

Annuncio economico

Turchia

Turchia

1.354 km

PRESSA IDRAULICA MONOAZIONE DA 150 TON TIPO H

CRONOSSTECHCHP 150

Chiama

Condizione: nuovo, Anno di produzione: 2025, forza di pressatura: 150 t, larghezza tavola: 800 mm, lunghezza del tavolo: 1.000 mm, corsa: 500 mm, pressione di esercizio: 250 barra, Equipaggiamento: barriera di sicurezza a luce, documentazione / manuale, CRONOSSTECH CHP 150

H Frame Single Acting Hydraulic Press – 8 Guides

General Description

The CRONOSSTECH CHP series H-frame single acting hydraulic presses are industrial machines with rigid steel construction, designed for sheet metal forming, straightening, assembly, and die pressing applications. Thanks to its 8-guide H-frame body design, it provides stable, balanced, and repeatable operation during pressing. The CHP 150 model is developed for medium-tonnage applications with a focus on reliable performance and long service life.

CHP Series – Structural Features

CHP series presses are engineered with heavy-duty operations in mind. The frame and carrier parts are stress-relieved by vibration. Bronze Zr14 slide bearings ensure smooth load transfer and long-term stable operation.

⚙️ Standard Equipment

- Steel construction, 8-guide H-frame press body

- Stress-relieved frame and carrier parts via vibration

- Bronze Zr14 slide bearings

- Welding applications with WPQR & WPS approvals accredited by TÜRK-AK (EN ISO 15614-1:2017 / EN ISO 14731)

- Machine structure designed and manufactured in compliance with CE standards

- PLC-controlled hydraulic system

- Touch panel display (DELTA 7”)

- Adjustable ram stroke and tonnage control

- Automatic lubrication system

- Electronic filter contamination warning

- Hydraulic unit oil temperature and system status monitoring on display

- Cooling system

- Off-line filtration

- Two-hand control system

- Light barrier (standard for operator safety)

- SIEMENS – SCHNEIDER electrical components

📐 Technical Specifications – CHP 150

Type: Steel construction, 8-guide H-frame press body

Frame Material: St52 – ERDEMİR

Guide Bearings: Bronze Zr14

Capacity (Ram): 150 Ton

Moving Table Size: 800 × 1000 mm

Fixed Table Size: 800 × 1000 mm

Parallelism Tolerance: 120 micron/m

Perpendicularity Tolerance: 60 micron/m

Stroke (Ram): 500 mm

Min. Opening: 100 mm

Max. Opening: 600 mm

Stress Relief: Vibration stress relief

Ppodpfx Aex N T Dzjaqsl

Welding Application: Welding applications certified to EN ISO 15614-1/2017, accredited by TÜRK-AK (supervised by welding coordination engineers certified to EN ISO 14731)

Max Operating Pressure: 250 Bar

Total Motor Power: 18.5 kW – IE3

Main Pump: 32 cm³ – REXROTH or PARKER

Moving Table Fast Descent Speed: 150 mm/s

Moving Table Pressing Speed: 12 mm/s

Moving Table Return Speed: 170 mm/s

Main Cylinder Bore: Ø280 mm – Ck45

Approximate Press Height: 3650 mm

Approximate Press Width: 2950 mm

Approximate Press Depth: 2000 mm

Height of Lower Table from Floor: 1250 mm

Main Filling Valve: NG 100

Hydraulic Unit: REXROTH or PARKER

Cooling System: EMMEGI – CIESSE – PARKER

Off-line Filtration: REXROTH or PARKER

Linear Position Transducer: NOVATECHNIK or TURCK

PLC Application: DELTA

Touch Panel Display: DELTA 7”

Switching Components: SIEMENS – SCHNEIDER

Approximate Weight: 7 Ton

Production Note

This machine is manufactured in Turkey by CRONOSSTECH.

Annuncio economico

Turchia

Turchia

1.354 km

PRESSA IDRAULICA MONOEFFETTO TIPO H DA 100 TON

CRONOSSTECHCHP 100

Chiama

Condizione: nuovo, Anno di produzione: 2025, forza di pressatura: 100 t, larghezza tavola: 800 mm, lunghezza del tavolo: 1.000 mm, corsa: 500 mm, pressione di esercizio: 250 barra, Equipaggiamento: barriera di sicurezza a luce, documentazione / manuale, CRONOSSTECH CHP 100

H-Frame Single-Acting Hydraulic Press – 8 Guide Slideways

General Description

The CRONOSSTECH CHP series H-frame single-acting hydraulic presses are industrial presses with a rigid steel construction, designed for sheet metal forming, straightening, assembly, and die pressing applications. Thanks to its 8-slide H-frame structure, it ensures high stability and repeatable precision during pressing operations.

CHP Series – Structural Features

CHP series presses are engineered for heavy-duty operating conditions. The frame and carrier components are stress-relieved by vibration. The bronze Zr14 material used for the slide bearings offers long service life and stable operation.

Key Advantages

- 8-slide H-frame construction

- Vibration-stress relieved steel body

- Welding applications in compliance with ISO standards

- PLC controlled operation with touchscreen interface

- Design focused on operator safety and process stability

⚙️ Standard Equipment

- Steel construction, 8-guide H-frame press body

- Vibration-stress-relieved frame and carrier parts

- Bronze Zr14 slide bearings

- WPQR & WPS approved welding applications with TÜRK-AK accreditation (EN ISO 15614-1:2017 / EN ISO 14731)

- Machine structure designed and manufactured in accordance with CE standards

- PLC controlled hydraulic system

- Touch screen panel (DELTA 7”)

- Adjustable ram stroke and tonnage control

- Automatic lubrication system

- Electronic filter contamination warning

- Hydraulic unit oil temperature and system status monitoring via display

- Cooling system and off-line filtration

- Two-hand control system

- Light curtain (standard for operator safety)

- SIEMENS – SCHNEIDER electrical components

📐 Technical Specifications – CHP 100

Type: Steel construction, 8-guide H-frame press body

Frame Material: St52 – ERDEMİR

Slide Bearing: Bronze Zr14

Capacity (Ram): 100 Tons

Moving Table Size: 800 × 1000 mm

Fixed Table Size: 800 × 1000 mm

Parallelism Tolerance: 120 micron/meter

Perpendicularity Tolerance: 60 micron/meter

Stroke (Ram): 500 mm

Min. Daylight: 100 mm

Max. Daylight: 600 mm

Weld Stress Relief: Vibratory stress relief

Welding Application: WPQR & WPS approved by TÜRK-AK, welding process certificate to EN ISO 15614-1:2017 (inspection by welding coordination engineers certified to EN ISO 14731)

Max. Operating Pressure: 250 Bar

Total Motor Power: 11 kW – IE3

Main Pump: 22 cm³ – REXROTH or PARKER

Moving Table Fast Down Speed: 150 mm/sec

Moving Table Drawing Speed: 12 mm/sec

Moving Table Return Speed: 170 mm/sec

Main Cylinder Inner Diameter: Ø230 mm – Ck45

Auxiliary Acceleration Cylinders: 2 pcs

Pedpfx Aaox N Tx Sjqjpl

Approx. Press Height: 3,400 mm

Approx. Press Width: 2,950 mm

Approx. Press Depth: 2,000 mm

Bottom Table Height from Floor: 1,250 mm

Pre-fill Valve: NG 100

Hydraulic Power Unit: REXROTH or PARKER

Cooling System: EMMEGI – CIESSE – PARKER

Off-line Filtration: REXROTH or PARKER

Linear Position Transducer: NOVATECHNIK or TURCK

PLC Application: DELTA

Touch Panel Display: DELTA 7”

Switchgear: SIEMENS – SCHNEIDER

Approx. Weight: 6.5 Tons

Production Note

This machine is manufactured by CRONOSSTECH in Turkey.

Annuncio economico

Zuchwil

Zuchwil

714 km

Pressa idraulica

Bunorm4S-500

Chiama

Condizione: eccellente (usata), Anno di produzione: 2014, Pressa idraulica Bunorm 4S-500

Produttore: Bunorm AG

Modello: 4S-500

Anno di costruzione: 2014

Forza di pressatura: 500 kN

Pressione massima: 225 bar

Peso: 3200 kg

Collegamento elettrico: 3×400 V + N + PE

Frequenza: 50 Hz

Ppedpfx Ajxfl Axoaqjl

Protezione: 20 A

Controllo: Siemens Simatic HMI Touch

Sistema di sicurezza: Barriera fotoelettrica SICK C4000

AMBITO DELL’OFFERTA

Incl., tra l’altro (elenco non esaustivo):

Pressa idraulica Bunorm 4S-500

L’esatto ambito dell’offerta è illustrato nella galleria fotografica.

La pressa idraulica Bunorm 4S-500 si distingue per la sua struttura robusta e una forza di pressatura di 500 kN con una pressione massima di 225 bar. Grazie alla costruzione solida e al peso di 3200 kg, questa pressa è particolarmente adatta a processi di produzione impegnativi. Il controllo integrato Siemens Simatic HMI Touch consente un utilizzo preciso e intuitivo. Il moderno sistema di sicurezza con barriere fotoelettriche SICK C4000 garantisce un elevato livello di protezione per l’operatore. Questa macchina rappresenta la soluzione ideale per le aziende che danno importanza ad affidabilità, precisione e sicurezza.

Non si assume alcuna responsabilità per la correttezza, completezza e attualità delle informazioni fornite.

Annuncio economico

Schmölln

Schmölln

1.005 km

Presse a doppia colonna

HYLATECHNIKHESSP 100*1,5*XA4

Chiama

Anno di produzione: 1984, Condizione: usata, Pressione 100 t

Larghezza colonna 1000 mm

Corsa 150 mm

Superficie del tavolo 1000 x 700 mm

Distanza tavola/ram 500 mm

Corsa del cuscino dello stampo 180 mm

Superficie dello stampo 1000 x 700 mm

Fori dello stantuffo x profondità 50 mm

Velocità di corsa 85 colpi/min

Foro del trunnion (profondità x diametro) 85 x 50 mm

Scanalature di serraggio 22 DIN 650

Forma diagonale

Numero di scanalature di serraggio 2

Larghezza della lastra 400 mm

Lunghezza della lastra 1000 mm

Spazio richiesto circa 3,0 x 3,0 x 3,0 m

Peso della macchina circa 8 tonnellate

Potenza totale richiesta 30,2 kW

- Regolazione fine della corsa

- Smorzamento dell'impatto di taglio

- Estrazione dell'olio

- 2 cilindri

- Avanzamento a rulli di Dreher, tipo WAV, controllo PMS3000 di Dreher

- Cabina insonorizzata

- La macchina è stata revisionata nel 2001 e dotata di un nuovo sistema di controllo SIMATIC OP17 della SIEMENS.

equipaggiato

Ppodpfx Asfn Apzoaqel

Annuncio economico

Schmölln

Schmölln

1.005 km

Presse a doppia colonna

MÜLLERSZ 40.30.1

Chiama

Anno di produzione: 1981, Condizione: usata, Pressione 40 t

Larghezza dello stand 600 mm

Corsa 160 mm

Dimensioni del tavolo 560 x 400 mm

Altezza di installazione 360 mm

Foro dello slittone 40 H 7 DIN 810 mm

Capacità olio 500 litri

Velocità di ritorno 200 mm/sec

Pressione/corsa del cuscino dello stampo 60

Forza di espulsione 25 t

Potenza totale richiesta 15 kW

Spazio richiesto circa 1,44 x 0,95 x 2,54 m

Velocità di pressatura 27 mm/sec

Velocità di ritorno 200 mm/min

con cuscino idraulico per stampi Velocità:

Ppsdpfx Aaeb U Hw Teqel

Velocità di avanzamento rapido 240 mm/s regolabile in continuo

Annuncio economico

Schmölln

Schmölln

1.005 km

Presse a doppia colonna

EDELHOFFHZP 100

Chiama

Anno di produzione: 1980, Condizione: usata, Pressione 100 t

Larghezza della colonna - mm

Corsa 350 mm

Pjdpfxodlxcte Aaqjpl

Dimensioni del tavolo 1150 x 700 mm

Potenza totale richiesta 11 kW

Peso della macchina circa t

Spazio richiesto circa m

con smorzamento dell'impatto di taglio e cuscino di trafilatura

Macchina senza quadro elettrico

Sigillo di Fiducia

Rivenditori certificati da Machineseeker

Annuncio economico

Ennepetal

Ennepetal

1.122 km

Pressa idraulica

SORG500 To Viersäulenpresse S 500-2K

Chiama

Condizione: ristrutturata (usata), Anno di produzione: 2020, pressione:500 t

larghezza di passaggio:1100 mm

corsa:600 mm

peso della macchina ca.:ca. 22,8 t

Ppedpfxjffamvs Aaqjl

Superficie del tavolo:1100 x 800 mm

superficie dello slittone:1100 x 800 mm

Apertura alla luce del giorno:800 mm

Idraulico:300 bar

velocità di chiusura: 60-200 mm/sec

velocità di pressatura:0 - 9,5 mm/sec

velocità di apertura: 28-200 mm/sec

Altezza del tavolo sopra il livello del suolo:900 mm

altezza sul pavimento:5100 mm

peso del pezzo in lavorazione max.:2000 kg

peso del pezzo in lavorazione top:1000 kg

altezza sale:min. 6500 mm

Numero di cilindri di pressatura:1 St.

numero di cilindri di azionamento:2 St.

:ca. 270 Lt./min.

Capacità serbatoio olio:600 l

azionamento principale:75 kW

Tecnologia di controllo di Siemens:S 7

Controllo di sicurezza:PILZ Multi

Annuncio economico

Ennepetal

Ennepetal

1.122 km

Pressa idraulica

Calende220 To Viersäulenpresse Auflagetisch

Chiama

Condizione: nuovo, Anno di produzione: 2019, numero macchina/veicolo: DF0369, pressione:220 t

larghezza del passaggio:1500 mm

corsa:400 mm

peso della macchina ca.:5,2 t

dimensioni:ca. 4000 x 1950 x 2900 mm

capacità di ritorno:20 t

potenza totale richiesta:30 kW

Altezza massima di lavoro:500 mm

:10 mm

Ppedpofxyivsfx Aaqol

:10 mm/sec.

Velocità di ritorno:25 mm/sec.

velocità di traslazione rapida:10 mm/sec

piastra pestello:2000 x 400 mm

piastra da tavolo:2000 x 600 mm

altezza del tavolo sopra il pavimento:900 mm

:500 l

Raffreddamento olio (elettrico):1,5 kW (max)

sistema di misura:TURCK oder Balluff

:S7 1500 oder PILZ PSS 4000

Monitorare SIEMENS:oder OMRON

Annuncio economico

Ennepetal

Ennepetal

1.122 km

Pressa idraulica

Hidrobrasil1000 Tonnen Viersäulenpresse

Chiama

Condizione: nuovo, numero macchina/veicolo: DF0279, pressione:1000 t

larghezza del passaggio:1500 mm

corsa:800 mm

potenza totale richiesta:91 kW

peso della macchina ca.:68 t

dimensioni:3850 x 2900 x 6000 mm

capacità di ritorno:100 t

Dimensioni del tavolo: 1500 x 2250 mm

Ppodpfx Aasfxyiyoqol

:1500 x 2250 mm

altezza del tavolo sopra il pavimento:1300 mm

velocità di pre-corsa:200 mm/sec

velocità di ritorno:200 mm/sec

Velocità di pressione: 10 mm/sec

:1200 l

Raffreddamento olio (elettrico):1,5 kW (max)

Altezza massima di lavoro: 1000 mm

:200 mm/sec

Monitor:12 Zoll

Annuncio economico

Ennepetal

Ennepetal

1.122 km

Pressa idraulica

Hidrobrasil110 Tonnen 4-Säulenpresse

Chiama

Condizione: nuovo, Anno di produzione: 2018, numero macchina/veicolo: DF0116 - Rev.00, pressione:110 t

larghezza passaggio:1300 mm

corsa:1500 mm

Peso della macchina approssimativa.:12 t

dimensioni:ca. 2300 x 2090 x 4200 mm

capacità di ritorno:11 t

Altezza massima di lavoro:1500 mm

pestello:1730 x 1100 mm

piastra da tavolo:1730 x 1100 mm

altezza del tavolo sul pavimento:700 mm

Pjdpfx Ajdxvfleaqjpl

diametro della colonna:140 mm

Spessore della piastra ram:100 mm

spessore della piastra di serraggio:100 mm

Livello di rumore (Max.) :67 dB (in inglese)

Corpo macchina colore:7035 RAL

Parti in movimento del colore:2009 RAL

Colore altri componenti:7021 RAL

Colore del balcone e dell'involucro:1021 RAL

capacità motoria:18 kW

Avvicinamento velocità max. &300 mm/sec

velocità di pressione:15 mm/sec

Capacità del serbatoio dell'olio:150 l

Sistema di controllo Siemens:S7 1200

Ti facilitiamo la ricerca

Riceverete subito e gratuitamente nuove offerte via e-mail.

Puoi disattivare l'agente di ricerca facilmente in qualsiasi momento

presse idrauliche doppia/quadrupla colonna usato (322)

Cerca su Machineseeker con più di 200.000 macchine usate.Sfoglia le denominazioni delle macchine più popolari:

- Cilindri Di Pressatura

- Cilindri Idraulici

- Cilindro Idraulico

- Cilindro Idraulico Doppio Effetto

- Doppia Guida Per Augnature

- Doppia Macchina Da Stampa

- Doppia Pompa Idraulica

- Doppio Estrusore A Vite

- Frizione Idraulica

Informati ora

+49 201 857 86 152

+49 201 857 86 152

Pubblica un annuncio ora

*per annuncio / mese