Sega a nastroCORMAK

HBS275

Sega a nastro

CORMAK

HBS275

Prezzo fisso IVA esclusa

1.349 €

Anno di produzione

2025

Condizione

Nuovo

Ubicazione

Siedlce

Mostra immagini

Mostra mappa

Dati della macchina

- Descrizione macchina:

- Sega a nastro

- Produttore:

- CORMAK

- Modello:

- HBS275

- Anno di produzione:

- 2025

- Condizione:

- nuovo

Prezzo e posizione

Prezzo fisso IVA esclusa

1.349 €

- Ubicazione:

- Brzeska 120, 08-110 Siedlce, Polska

Chiama

Dettagli dell'offerta

- ID dell'annuncio:

- A16883691

- Ultimo aggiornamento:

- il 07.01.2026

Descrizione

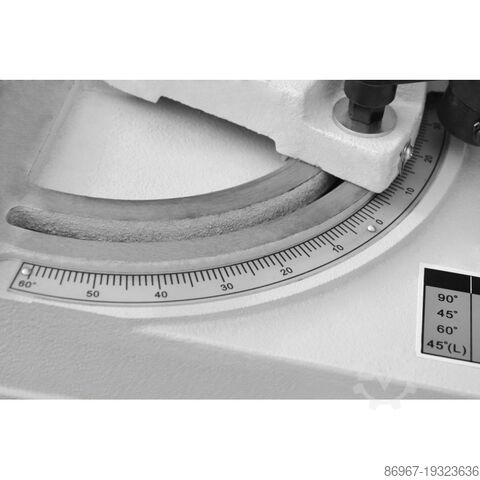

CORMAK HBS275 Band Saw for cutting pipes, profiles, and bars is widely used in all locksmith workshops where precision, quality, and cutting speed are critical. The model features a swiveling arm (0-60°), and the blade guides are carbide-based. The frame structure ensures accurate and quiet operation.

Machine Features

The horizontal metal band saw with a swiveling arm allows cutting in a plane perpendicular to the axis of the material as well as at any angle from 0 to 60°. The material can be fed manually or by any mechanical device, while the feed of the tool occurs automatically. The saw blade guides are equipped with special carbide plates and bearings, which greatly affect the guidance, longevity, straightness, accuracy, and cutting quality of the blade. Carbide guidance significantly reduces wear of both the machine and the saw blade. The machine is equipped with an efficient coolant pump with a closed-loop cooling system.

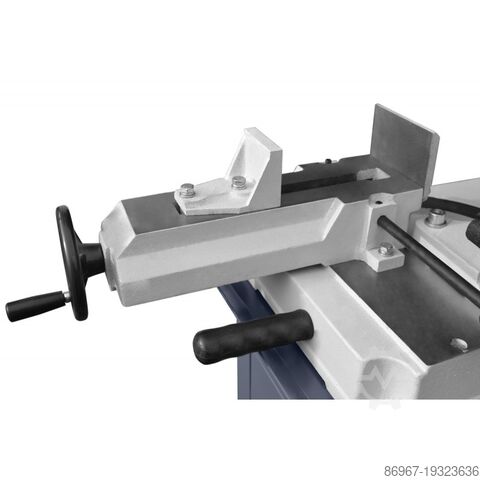

The saw arm is cast in one piece from iron and, combined with the use of a 27 mm wide blade, is fully capable of performing series cuts on both profiles and solid materials. The vice is mounted on an adjustable bed and comes with a quick-release clamp. The blade guides are fitted with hard metal (carbide) plates and a rolling bearing system. It’s the CARBIDE GUIDES that ensure precise and straight cuts.

The arm is equipped with an automatic blade tension sensor and is inclined at 25 degrees to extend blade life. A cleaning brush is mounted underneath for optimal cleanliness and blade performance. Power transmission is via a worm gear drive.

A cast iron workbench with a swiveling arm and a control panel on a separate arm is mounted to the base. During cutting, the main cutting motion is the movement of the saw blade, while the feed is the lowering of the arm. Arm lowering speed (cutting speed) is controlled by a hydraulic cylinder.

The feed speed is adjusted from the saw's control panel. There are two cutting blade speeds to choose from: 37.5 and 75 m/min. When the arm reaches the lowest position (after completing a cut), the drive is automatically switched off. Safety is provided by blade guards and micro switches that stop the motor after the cutting cycle or if any guard is opened. Additional protection switches the saw off automatically in case the blade breaks.

Power transmission is via a motor with a worm gearbox.

The motor with a thermal fuse protects against overheating during use.

Kljdoudi Unepfx Aarjl

Technical Data

TOTAL POWER: 1.5 kW

VOLTAGE: 400V 50Hz

ARM LOWERING CONTROL: hydraulic cylinder

BLADE DIMENSIONS: 2450 x 27 x 0.9 mm

BLADE SPEED: 37.5 / 75 m/min

VICE BASE HEIGHT: 900 mm

MACHINE DIMENSIONS (ARM UP) (L x W x H): 1720 x 800 x 1800 mm

WEIGHT: 215 kg

Cutting capacities (angle, round, rectangular/square):

0º: ø220, 260x140, 200x200 mm

45º R: ø160, 160x140, 160x160 mm

60º R: ø100, 120x100, 100x100 mm

Price does not apply to machines purchased in Poland.

L'annuncio è stato tradotto automaticamente e possono essersi verificati degli errori di traduzione.

Machine Features

The horizontal metal band saw with a swiveling arm allows cutting in a plane perpendicular to the axis of the material as well as at any angle from 0 to 60°. The material can be fed manually or by any mechanical device, while the feed of the tool occurs automatically. The saw blade guides are equipped with special carbide plates and bearings, which greatly affect the guidance, longevity, straightness, accuracy, and cutting quality of the blade. Carbide guidance significantly reduces wear of both the machine and the saw blade. The machine is equipped with an efficient coolant pump with a closed-loop cooling system.

The saw arm is cast in one piece from iron and, combined with the use of a 27 mm wide blade, is fully capable of performing series cuts on both profiles and solid materials. The vice is mounted on an adjustable bed and comes with a quick-release clamp. The blade guides are fitted with hard metal (carbide) plates and a rolling bearing system. It’s the CARBIDE GUIDES that ensure precise and straight cuts.

The arm is equipped with an automatic blade tension sensor and is inclined at 25 degrees to extend blade life. A cleaning brush is mounted underneath for optimal cleanliness and blade performance. Power transmission is via a worm gear drive.

A cast iron workbench with a swiveling arm and a control panel on a separate arm is mounted to the base. During cutting, the main cutting motion is the movement of the saw blade, while the feed is the lowering of the arm. Arm lowering speed (cutting speed) is controlled by a hydraulic cylinder.

The feed speed is adjusted from the saw's control panel. There are two cutting blade speeds to choose from: 37.5 and 75 m/min. When the arm reaches the lowest position (after completing a cut), the drive is automatically switched off. Safety is provided by blade guards and micro switches that stop the motor after the cutting cycle or if any guard is opened. Additional protection switches the saw off automatically in case the blade breaks.

Power transmission is via a motor with a worm gearbox.

The motor with a thermal fuse protects against overheating during use.

Kljdoudi Unepfx Aarjl

Technical Data

TOTAL POWER: 1.5 kW

VOLTAGE: 400V 50Hz

ARM LOWERING CONTROL: hydraulic cylinder

BLADE DIMENSIONS: 2450 x 27 x 0.9 mm

BLADE SPEED: 37.5 / 75 m/min

VICE BASE HEIGHT: 900 mm

MACHINE DIMENSIONS (ARM UP) (L x W x H): 1720 x 800 x 1800 mm

WEIGHT: 215 kg

Cutting capacities (angle, round, rectangular/square):

0º: ø220, 260x140, 200x200 mm

45º R: ø160, 160x140, 160x160 mm

60º R: ø100, 120x100, 100x100 mm

Price does not apply to machines purchased in Poland.

L'annuncio è stato tradotto automaticamente e possono essersi verificati degli errori di traduzione.

Venditore

Nota: Registrati gratuitamente o accedi, per visualizzare tutte le informazioni.

Invia richiesta

Telefono & Fax

+48 25 63... mostra

Potresti essere interessato anche a questi annunci.

Annuncio economico

Siedlce

Siedlce

1.359 km

Sega a nastro

CORMAKBS-128HDRC 400V

CORMAKBS-128HDRC 400V

Annuncio economico

Germania

Germania

1.060 km

Tornio centrale e tornio a mandrino di avanzamento

STRUNGURI ARADSN501x1500

STRUNGURI ARADSN501x1500

Annuncio economico

Schlüchtern

Schlüchtern

973 km

TORNIO

Voest AlpineDA 160

Voest AlpineDA 160

Annuncio economico

Mindelheim

Mindelheim

705 km

Sega a nastro

MIOTAL®S 170 G

MIOTAL®S 170 G

Annuncio economico

Wien

Wien

760 km

Unità di saldatura

FRONIUS TPS 5000 MIG MAG PULSTRANS PULS SYNERGIC 5000 / 500 MASCHINE

FRONIUS TPS 5000 MIG MAG PULSTRANS PULS SYNERGIC 5000 / 500 MASCHINE

Annuncio economico

Wiesbaden

Wiesbaden

974 km

Trapano a colonna

IXIONBSS-23 AV

IXIONBSS-23 AV

Annuncio economico

Germania

Germania

1.047 km

Tornio centrale e tornio a mandrino di avanzamento

PADOVANILABOR 230

PADOVANILABOR 230

Annuncio economico

Böblingen

Böblingen

808 km

Sega a nastro

ZIMMERZ 241-1/R

ZIMMERZ 241-1/R

Annuncio economico

Eislingen/Fils

Eislingen/Fils

792 km

Sezione Cesoia - Combinata

PEDDINGHAUS210/13

PEDDINGHAUS210/13

Annuncio economico

Wien

Wien

760 km

Unità di saldatura

FRONIUS MIG MAG TPS 3200 4000 5000ALU STAHL V2A SCHWEISSGERÄT

FRONIUS MIG MAG TPS 3200 4000 5000ALU STAHL V2A SCHWEISSGERÄT

Il tuo annuncio è stato cancellato con successo

Si è verificato un errore